Design Tools — 3D & 2D Fabrication¶

Reflections¶

This week we started Digital Prototyping. I have a background in Product Design so I worked a lot with 2D and 3D design softwares. I use Autocad for 2D shetches, and Solidworks for 3D modelling. I am really interested in learning Rhinoceros and Grasshopper to be able to design paramentric, but I am used to Solidworks interface so shifting is hard.

3D Design & Fabrication¶

3D modeling

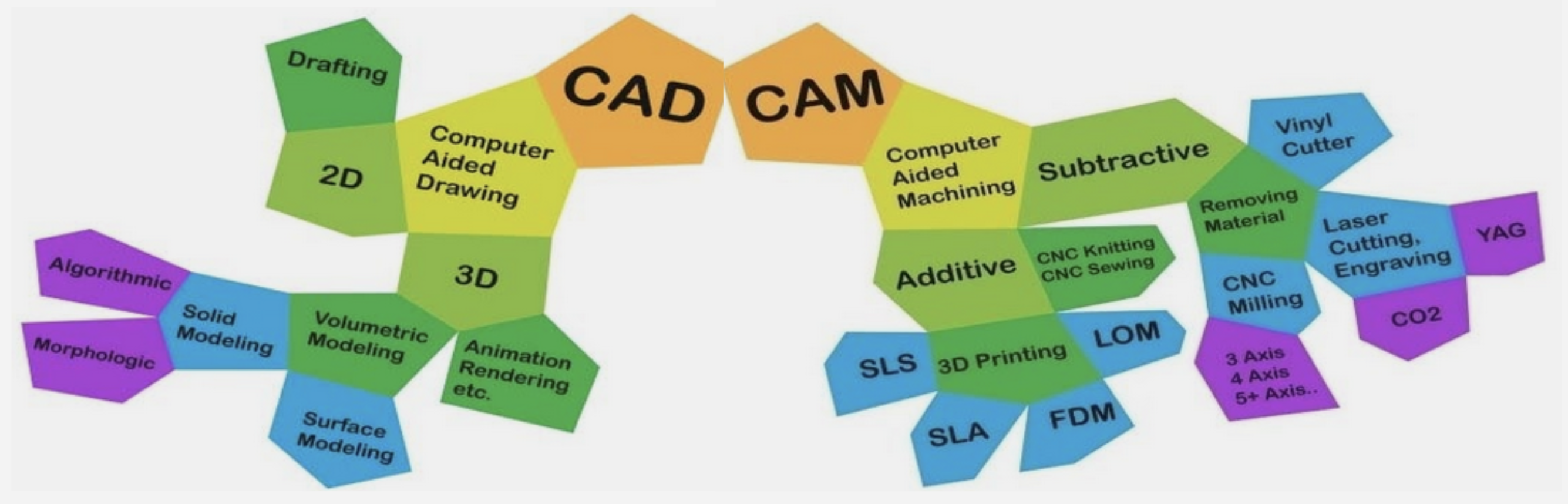

Graphic about Softwares for Design and Manufacturing

Mapping our familiar Softwares

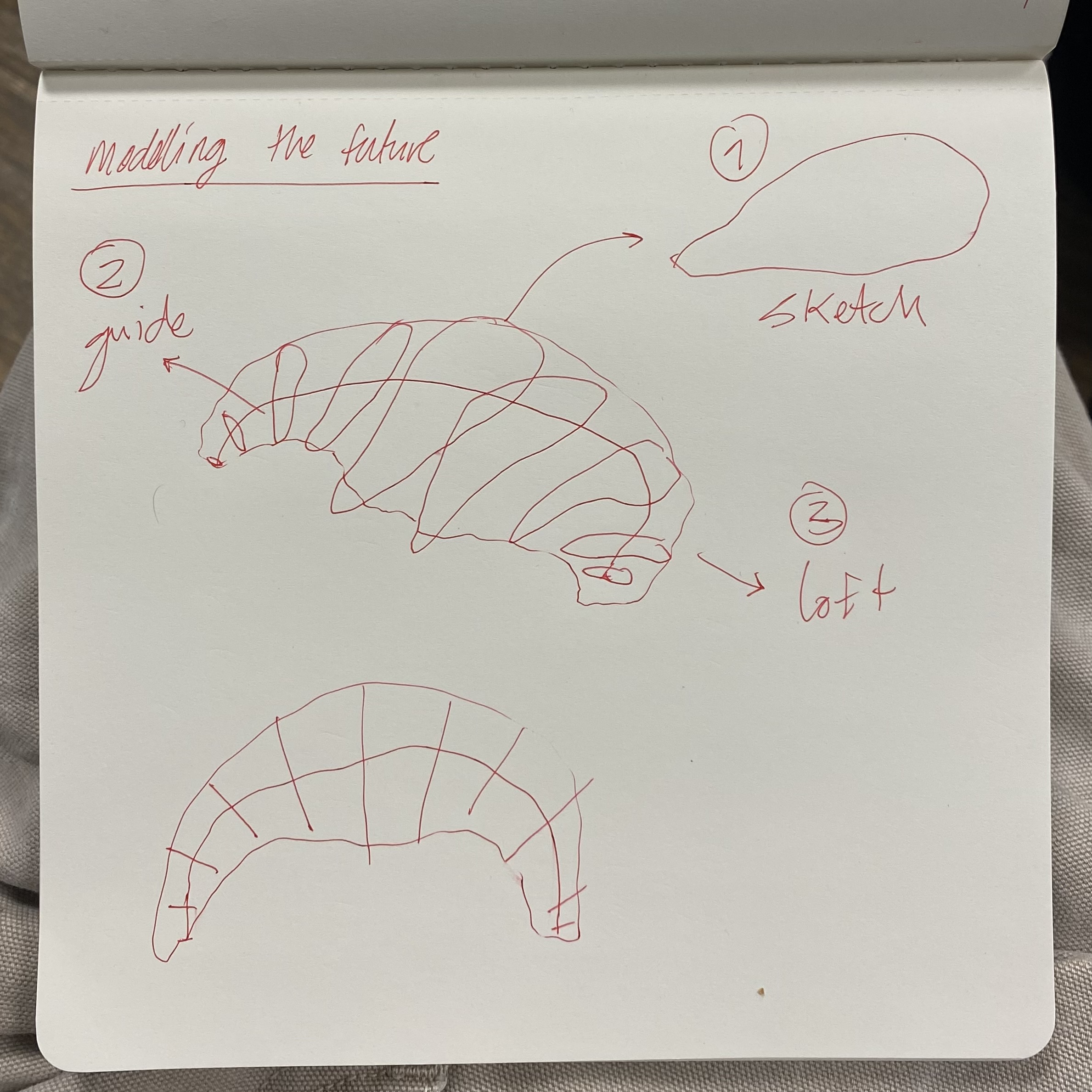

How to Parametrize a Croissant

First Assignment¶

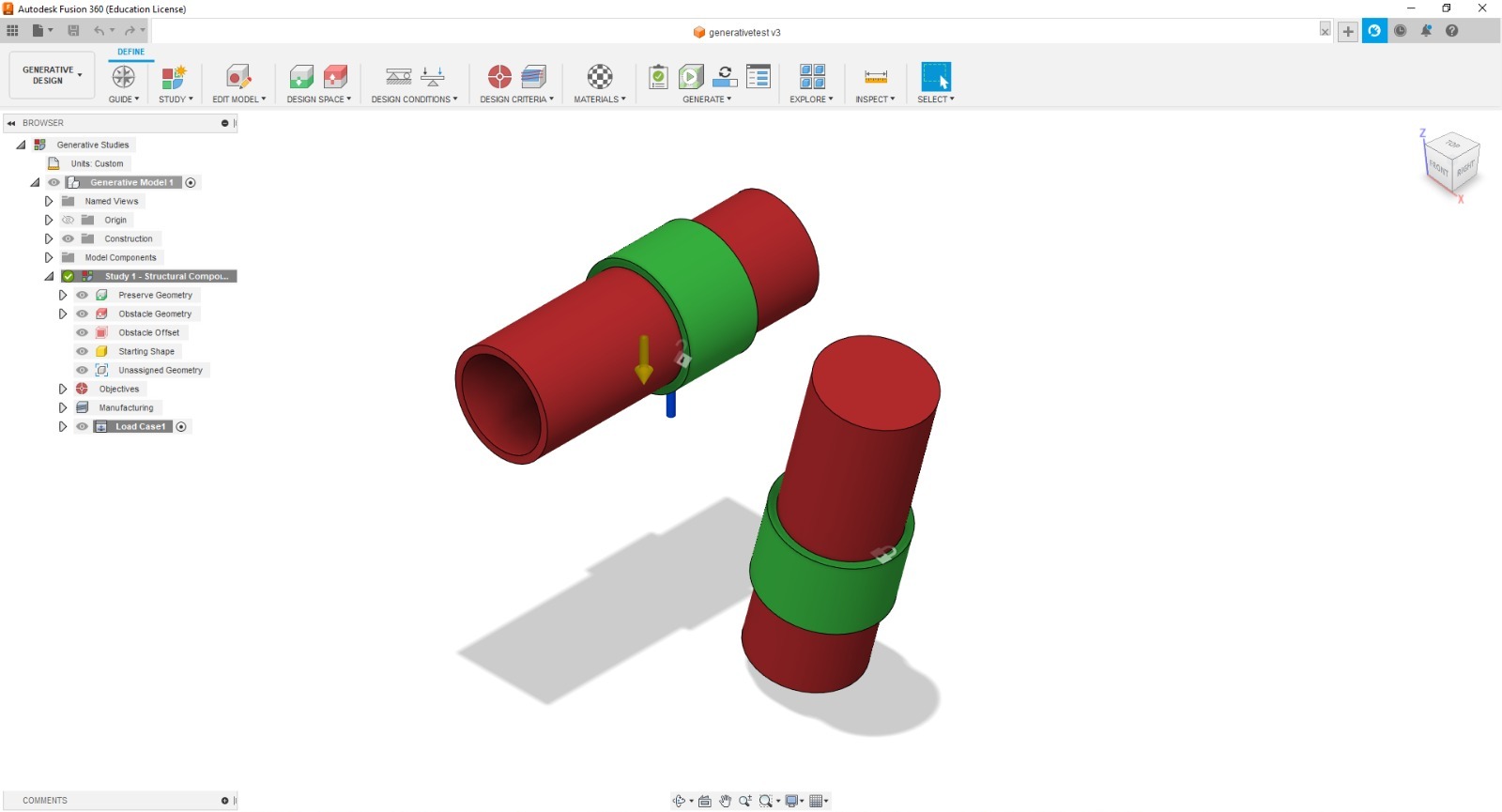

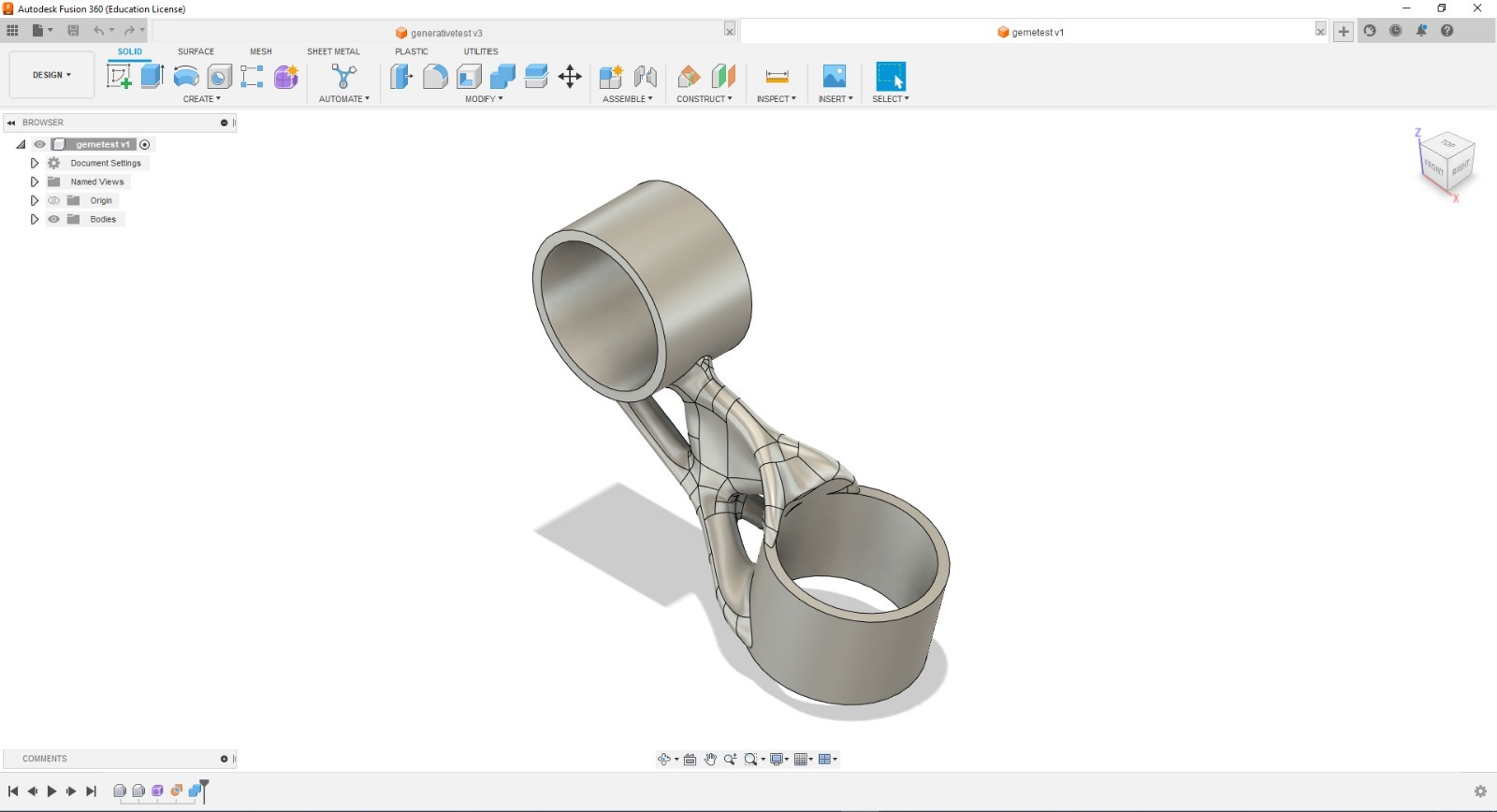

Generative Design — Fusion 360¶

Trying Fusion 360 and its Generative Design Tool

3D model and atributing carachteristics. Preserve and Obstacle geometries. Manufacturing Technique, and Loads and Constraints.

Generative final model.

Paramentric Design — Grasshopper¶

Introducing to Rhino and Grasshopper to be able to 3D model parametric designs.

2D Design & Fabrication¶

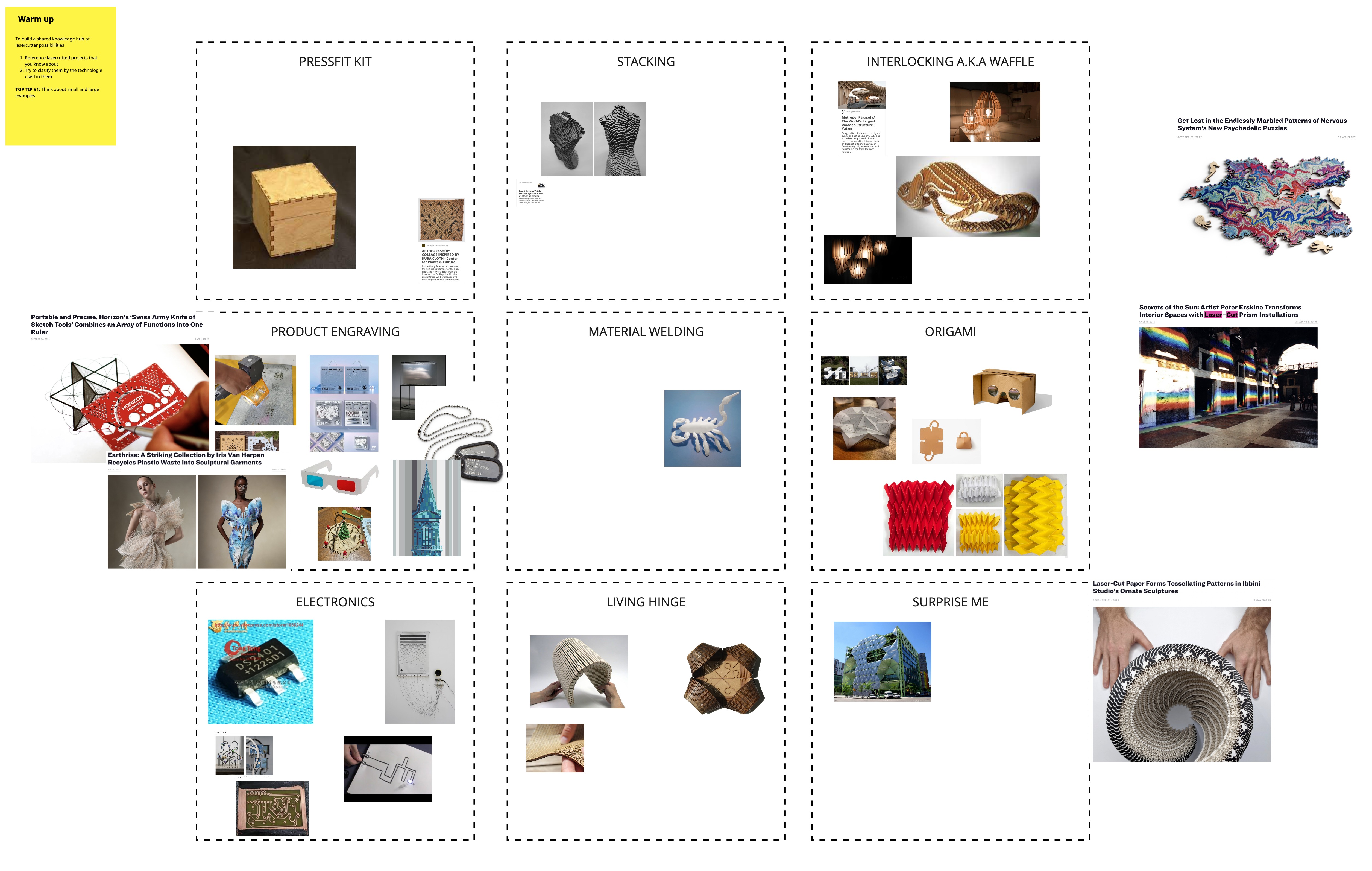

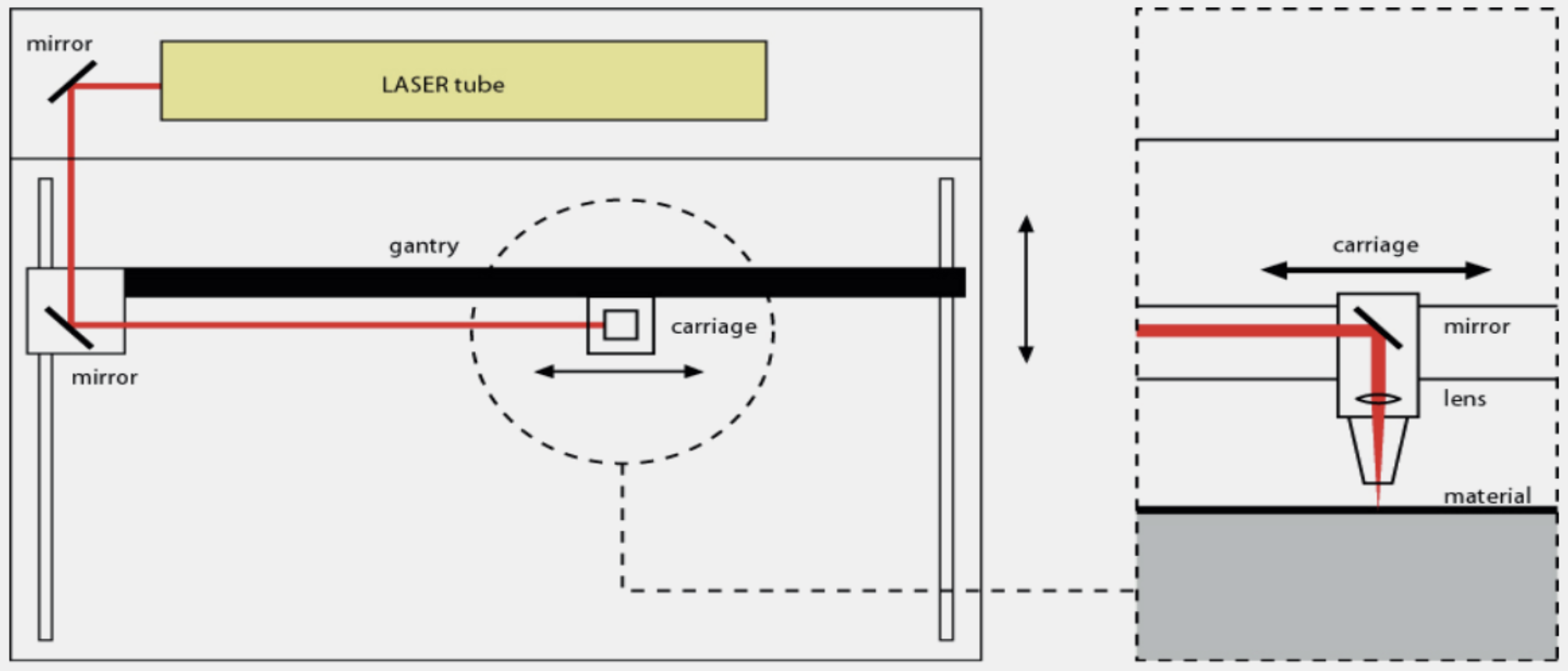

Laser Cut

CNC — Computer Numeric Component Laser — Light Amplification by Stimulated Emission of Radiation

Second Assignment¶

Laser Cut and how to assembly parts (tolerances).

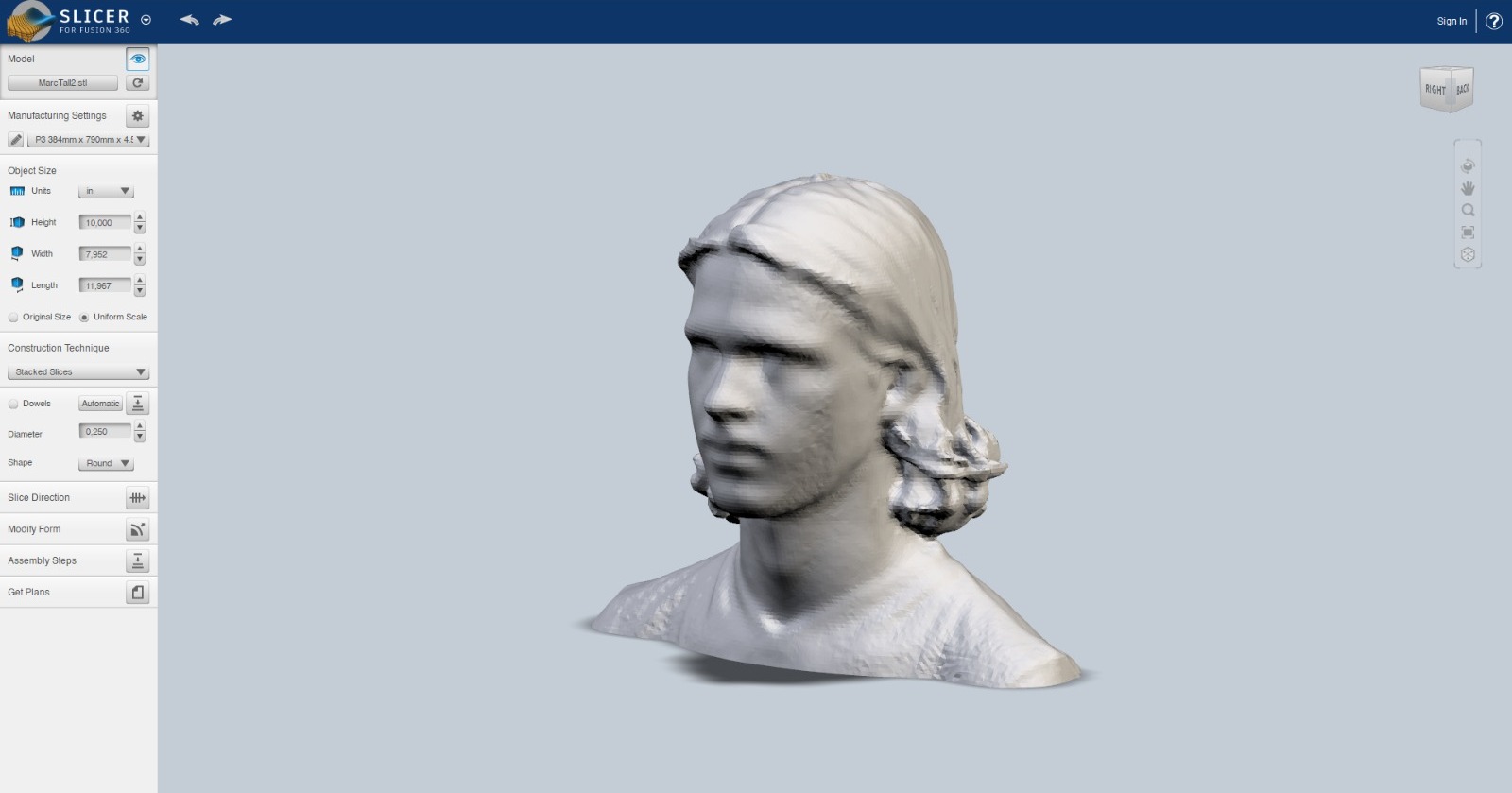

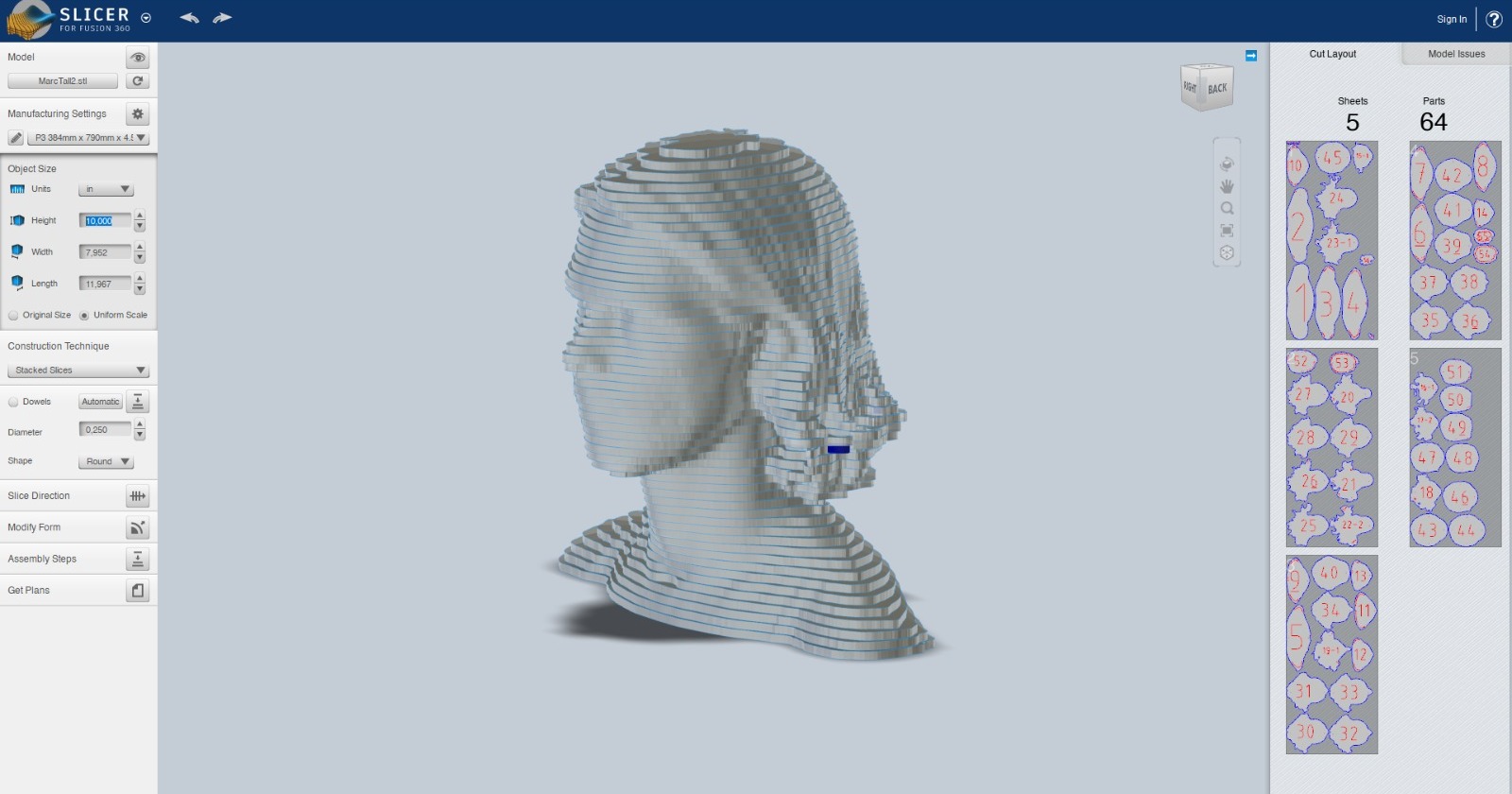

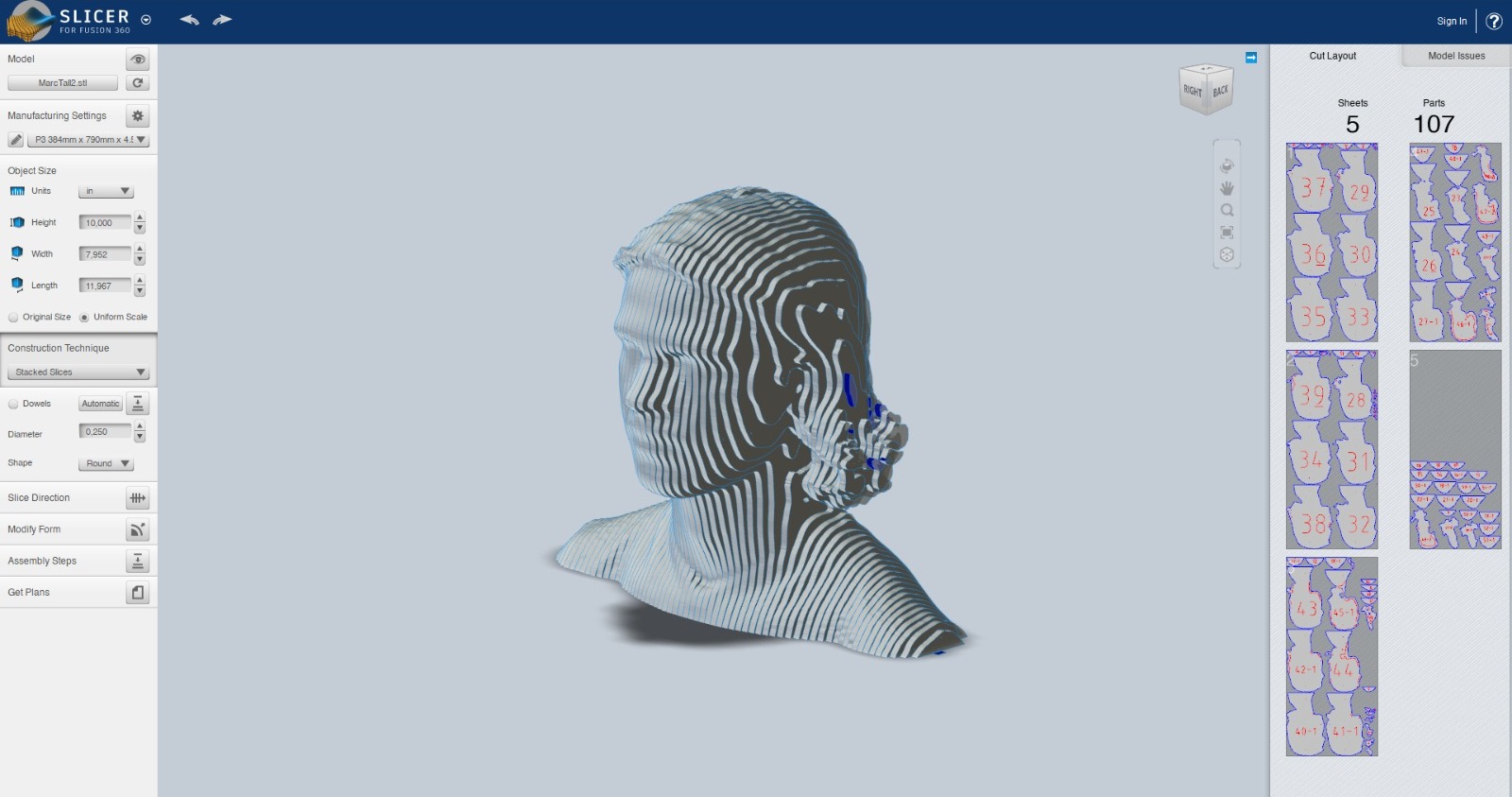

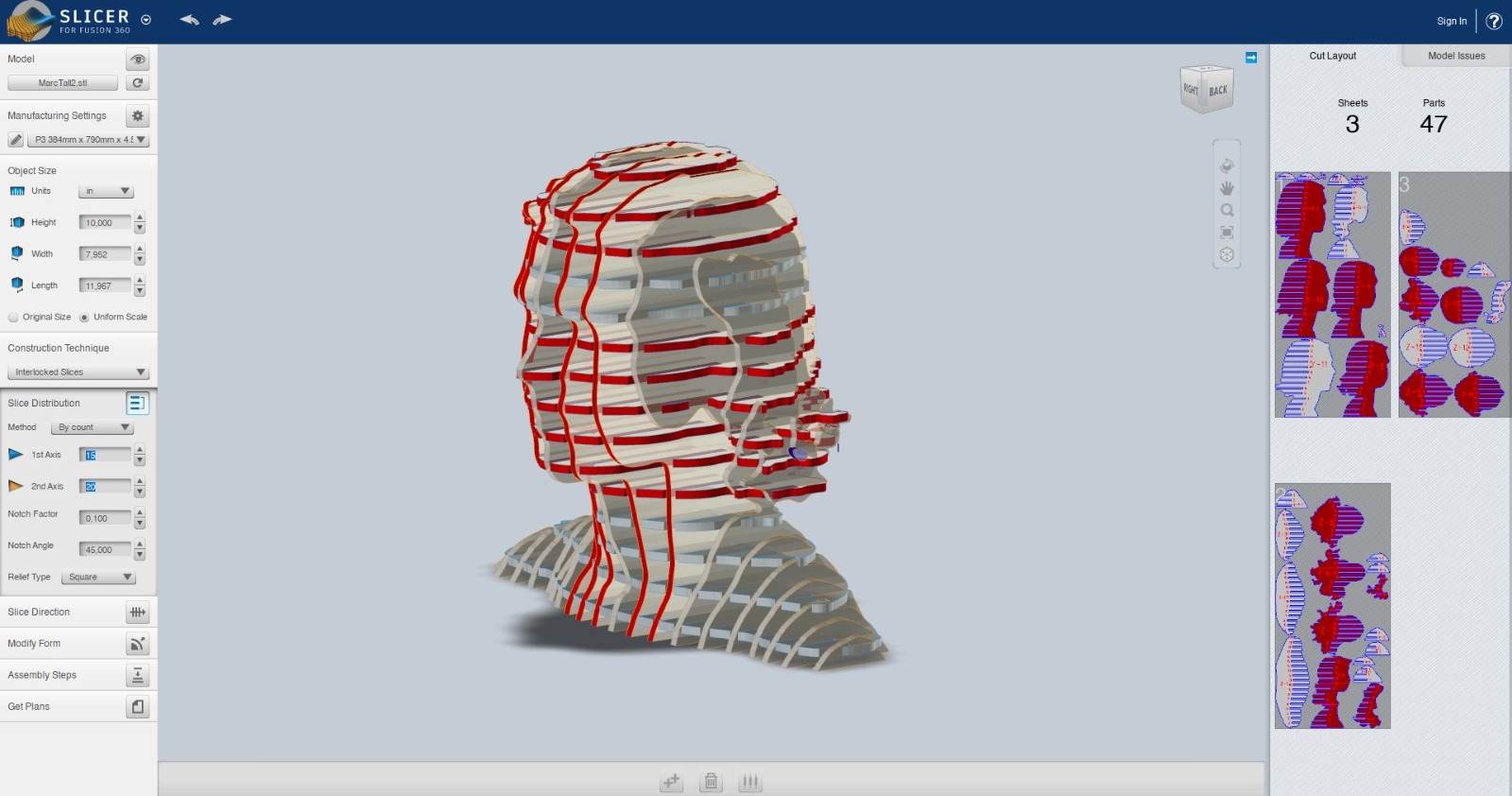

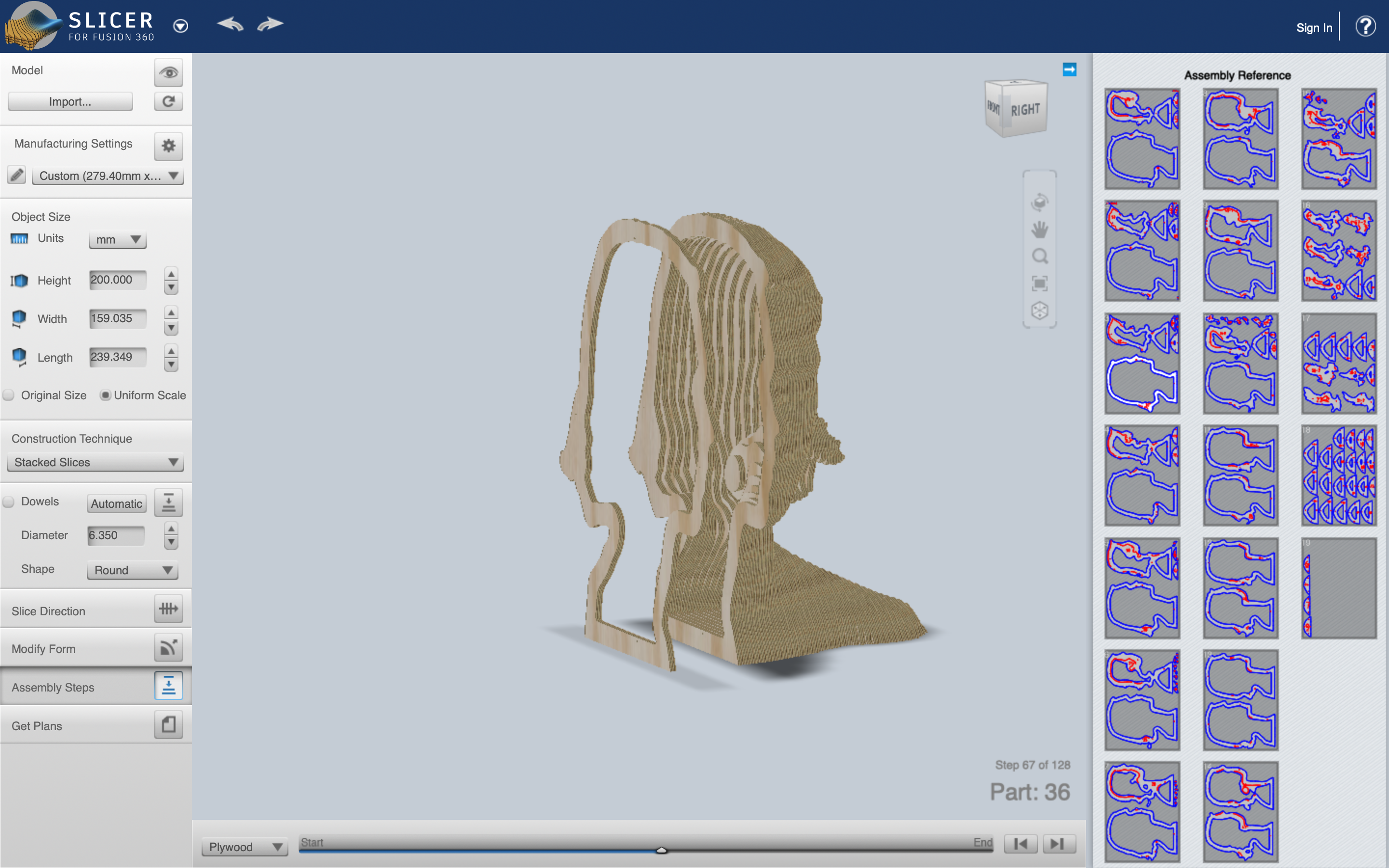

Slicing a 3D model to fabricate it with a Laser cut machine.¶

3D model

Generated with 3D Scanning — EM3D mobile app

Stacked Slices:

Slicing the model into planes. 2 different directions

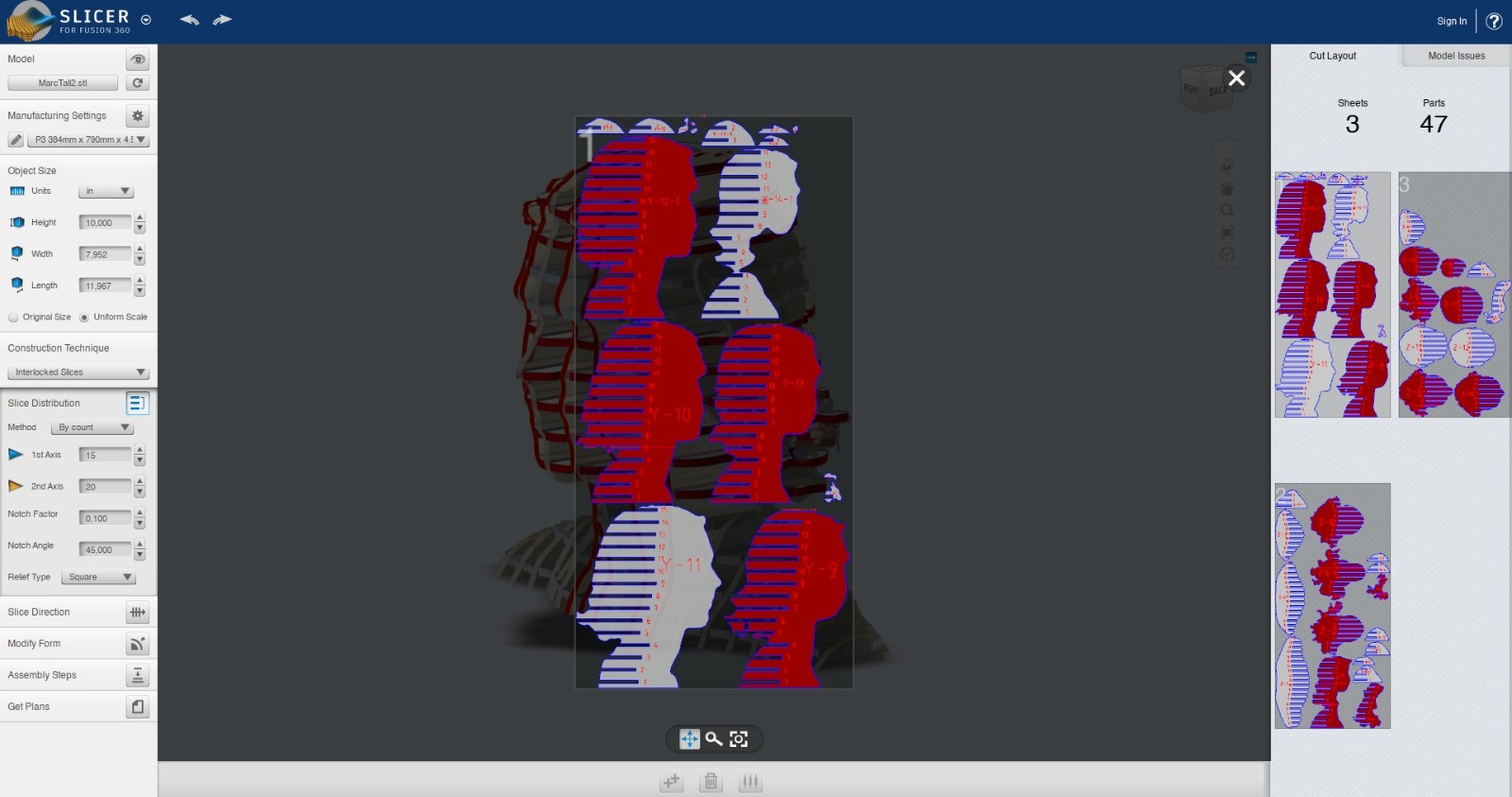

Interlocked Slices:

Slicing the model into inserted planes.

Folded Panels:

Made with a flexible plane, Origami-type. Paper folding

Sliced view of the model

With all the parts to be cutted in 2D

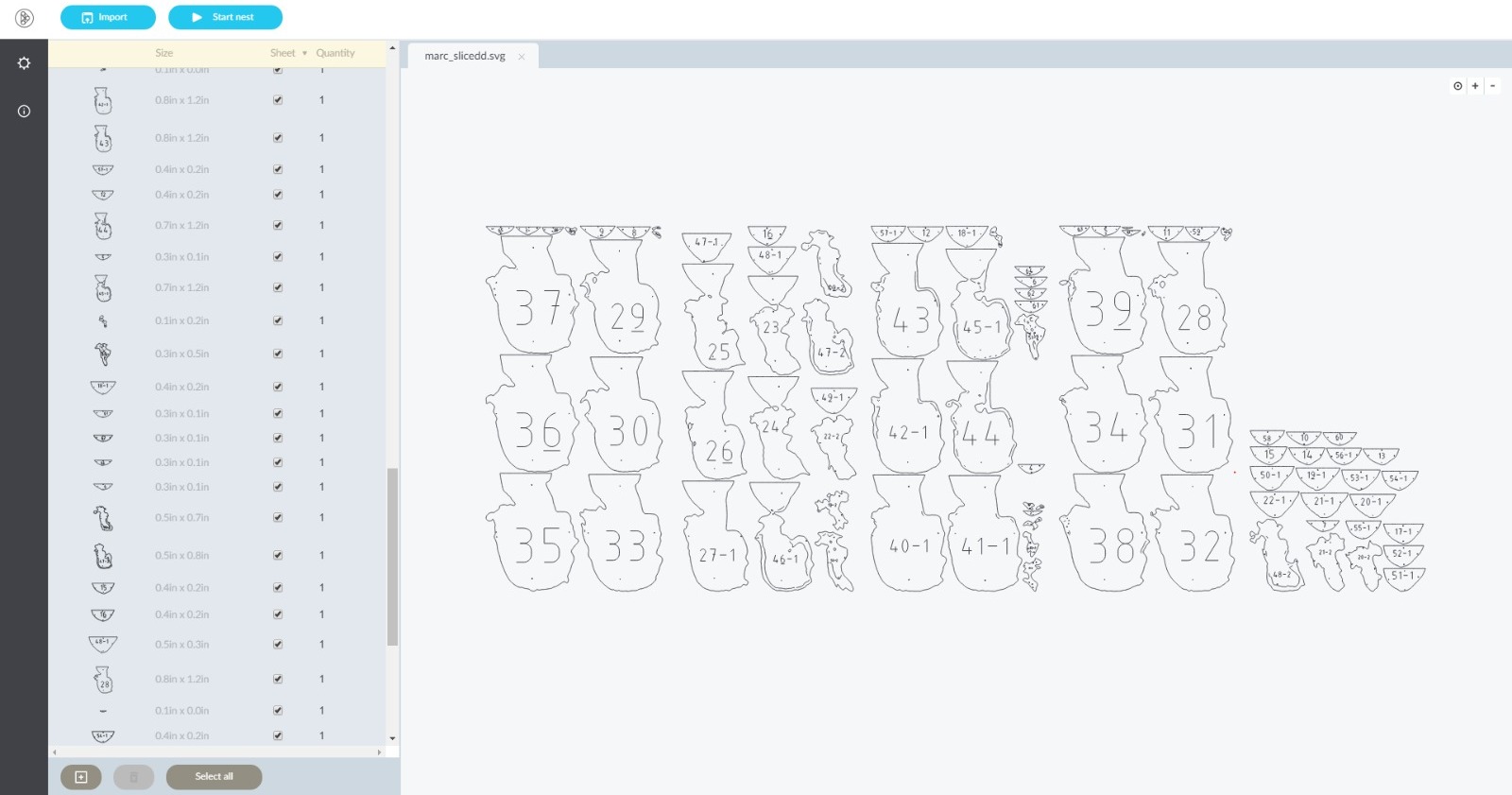

Deepnest:

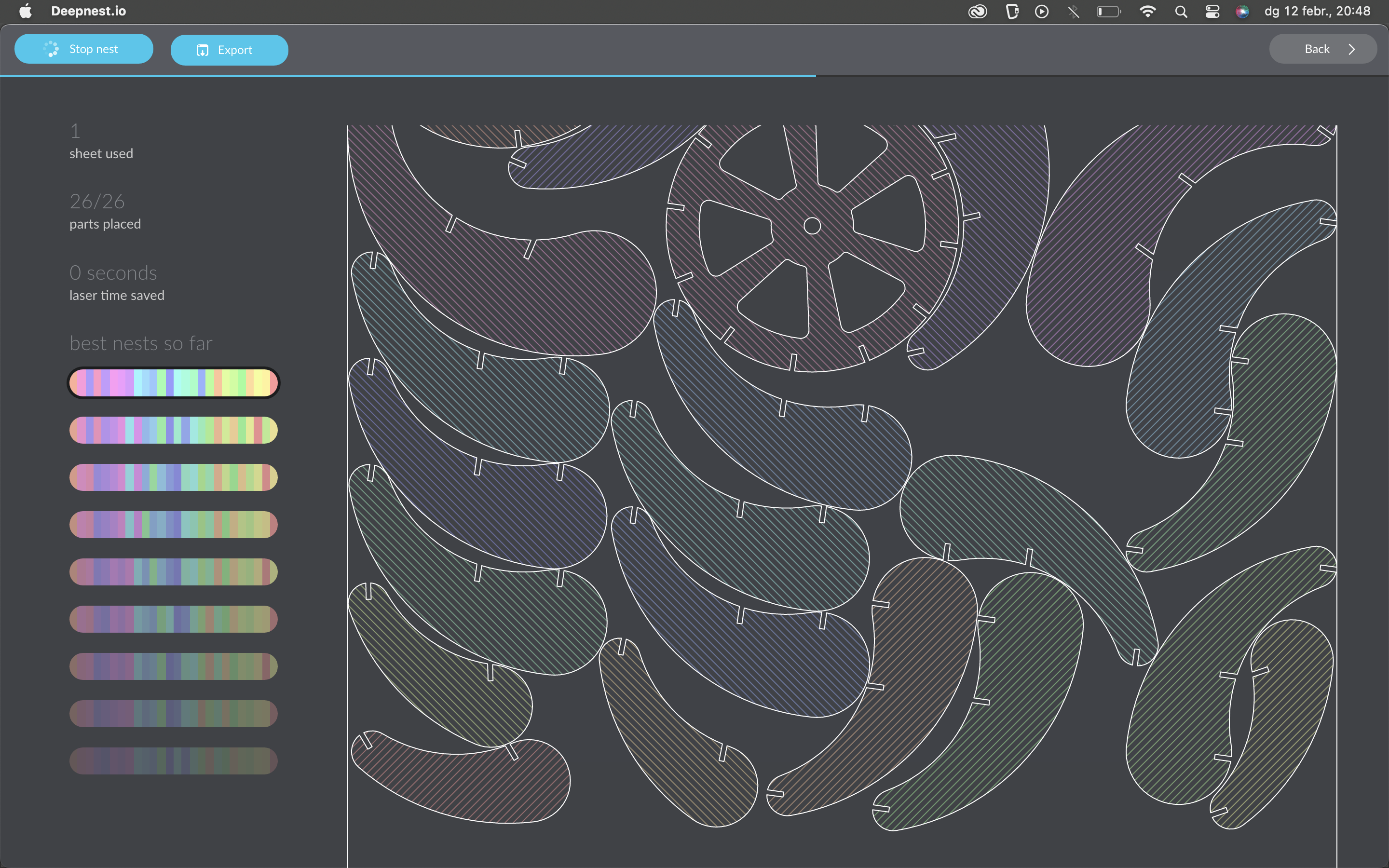

Using Deepnest software to place the parts to be cut with the least amount of material possible.

Model sliced empty to reduce weight and reduce amount of material waste

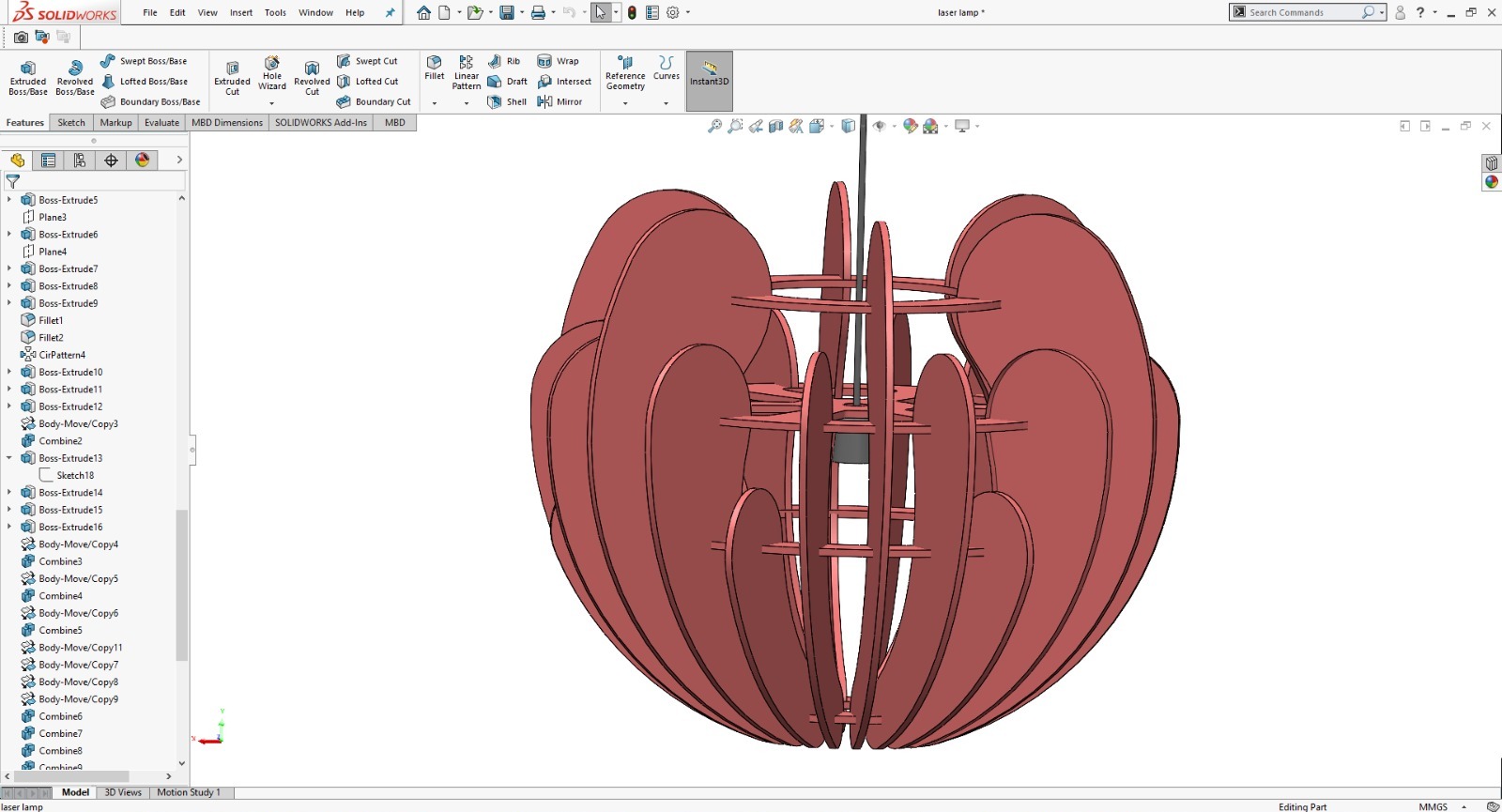

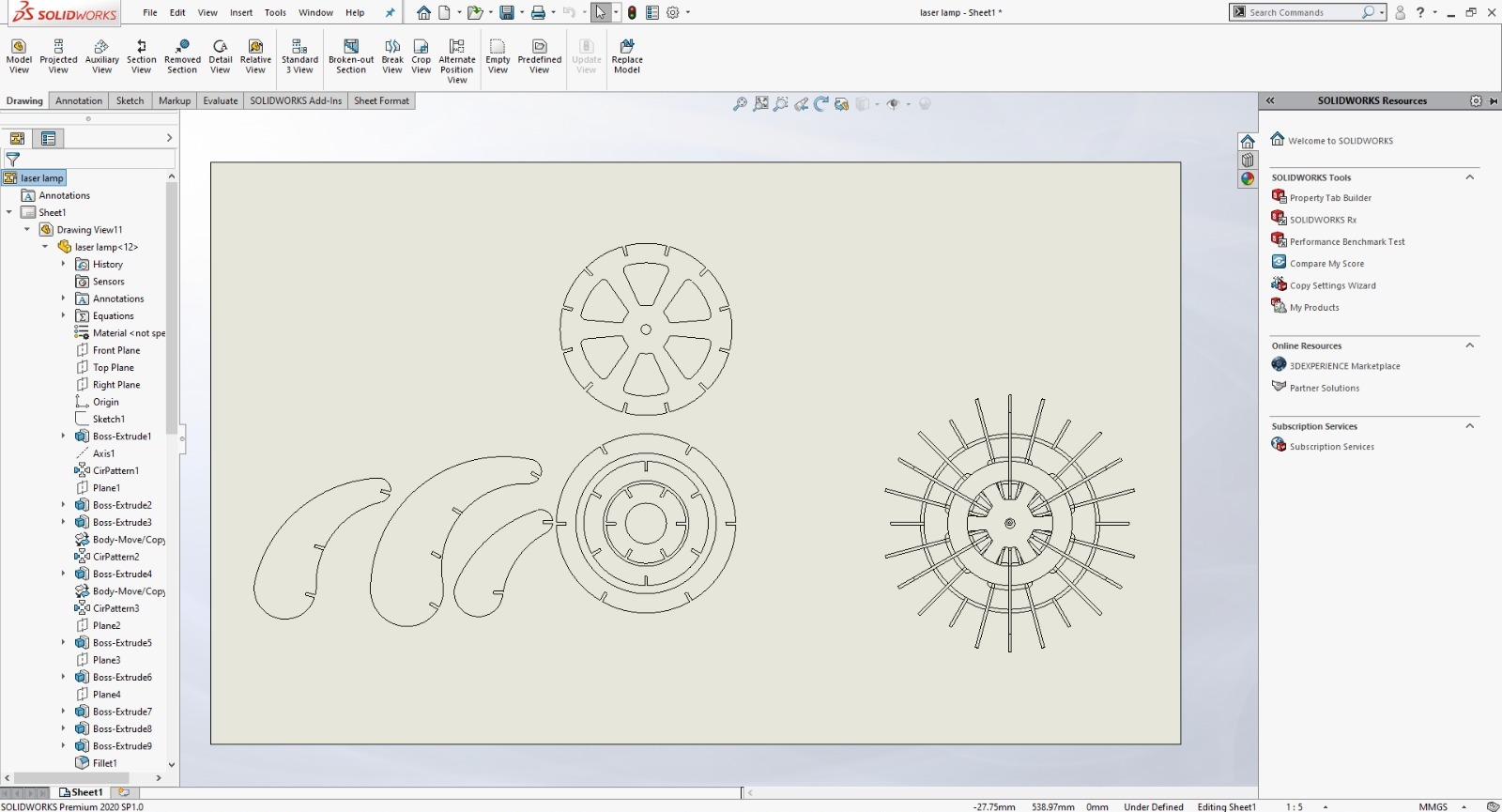

Design of a ceiling lamp to be produced with Laser Cut and assemble it without gluing.¶

Design 3D model in Solidworks

Generation of 2D Planes in Solidworks

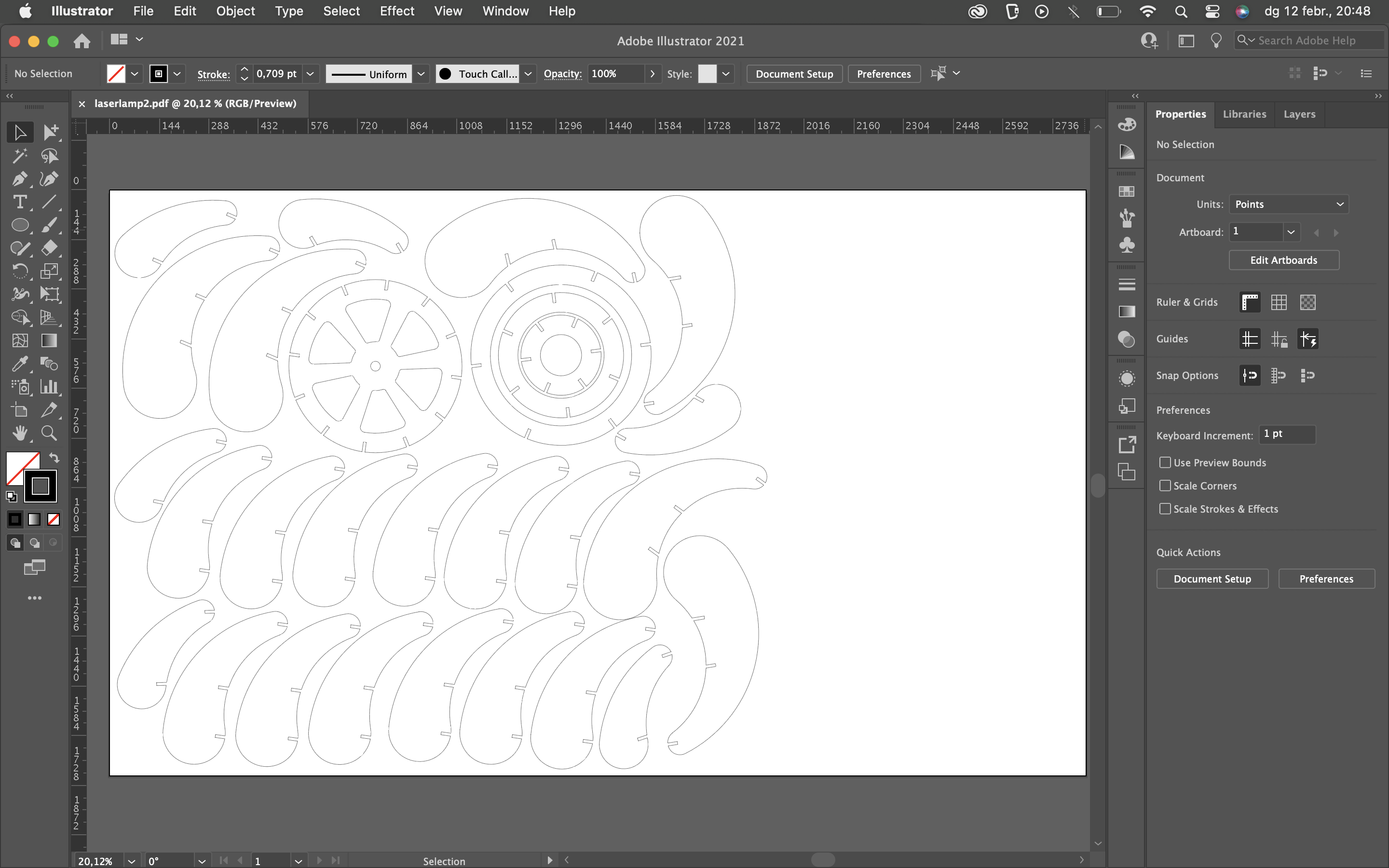

Duplication to have the necessary amount of each part type in Illustrator

Deepnest to optimise the placing of the parts in the laser machine

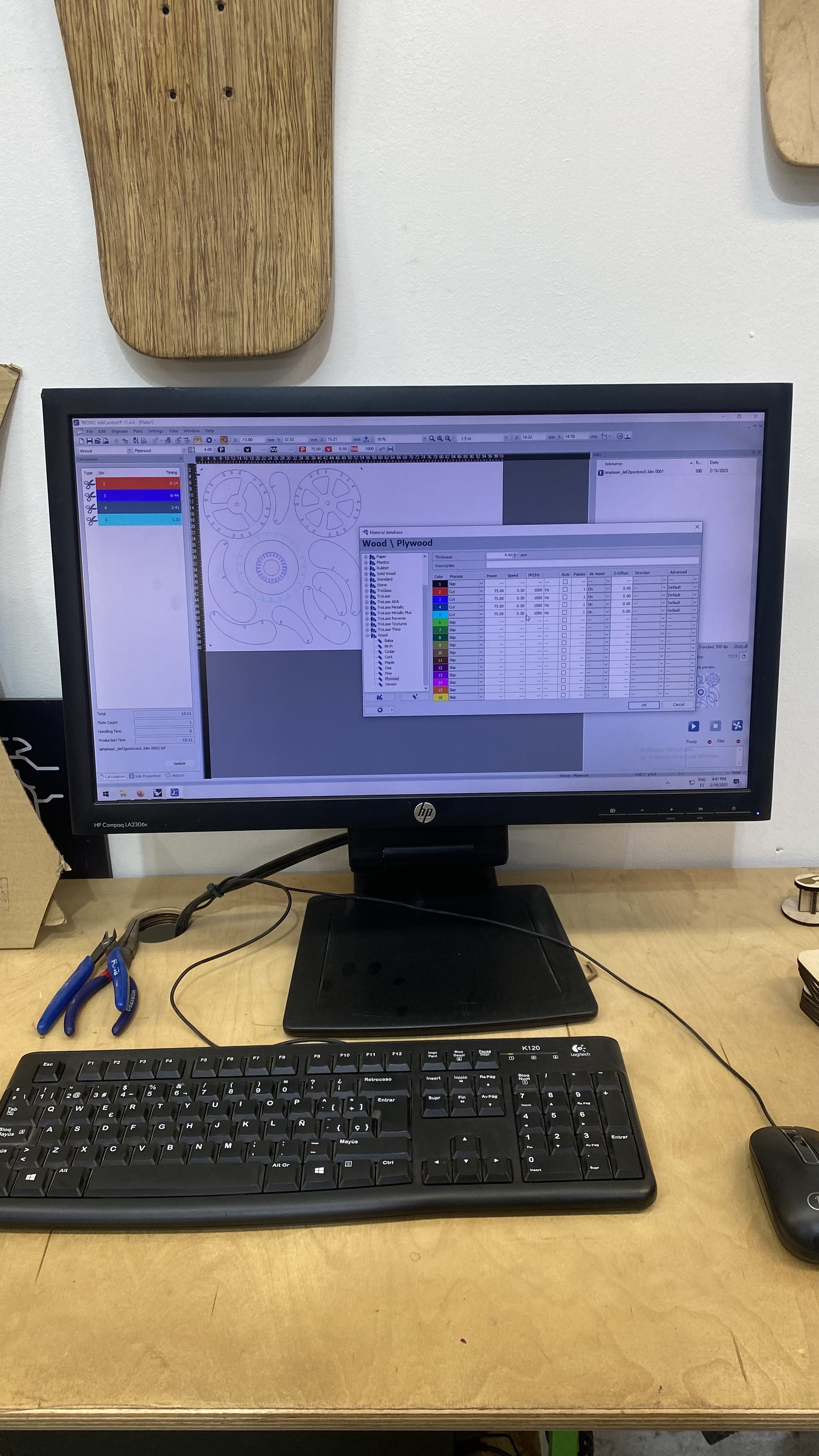

Configuring the settings of the laser cutter and separating the sketch into layers to determine the order of steps

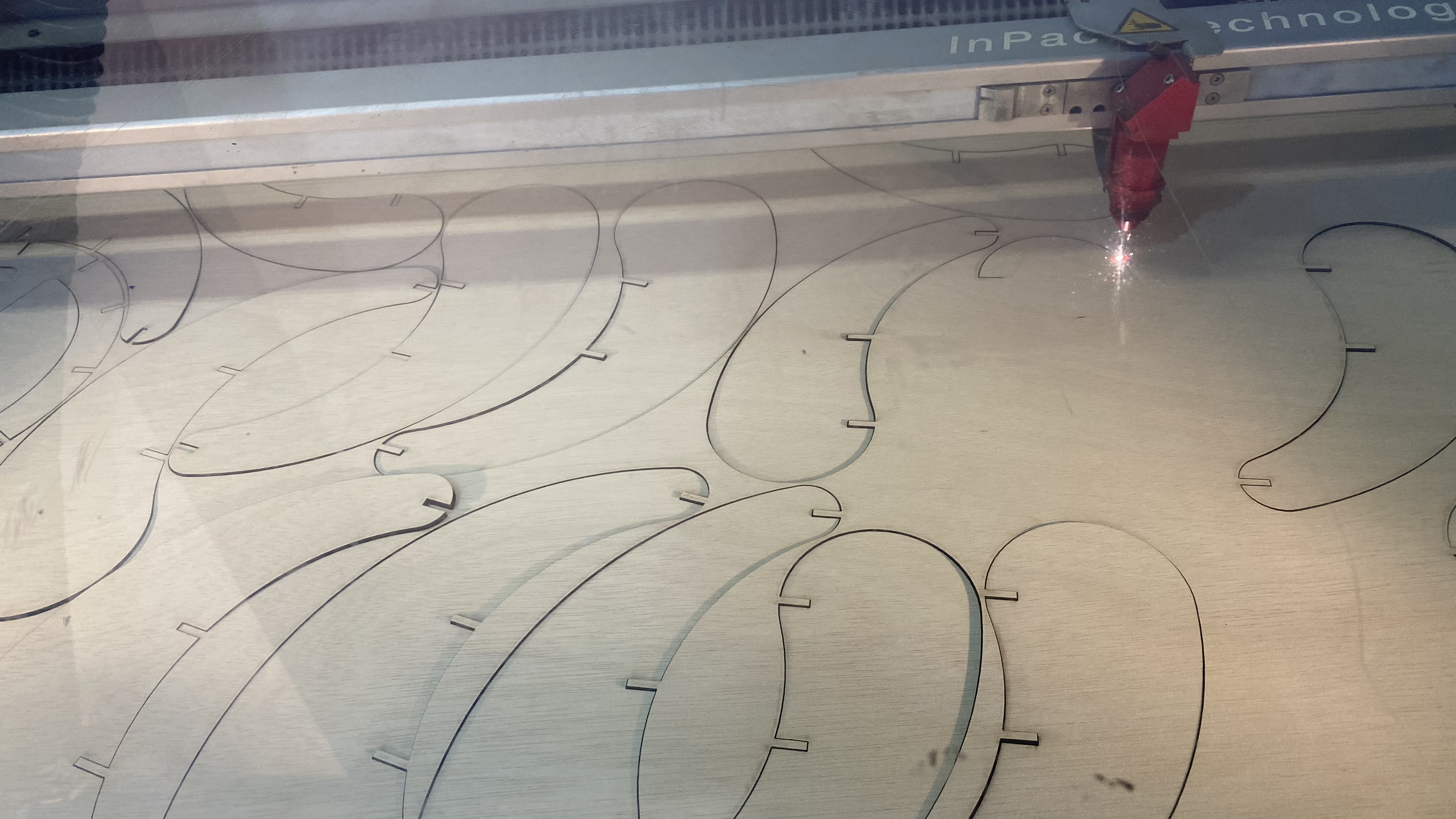

Laser Cutter Machine cutting the pieces

Pieces cutted, sanded and oiled.

Final Lamp in place